Machine park

Services provided by our machine park:

Plastic working of steel

- Bendmak CY 3-roller bending machine

- VARO PTE-3D CNC 3D wire bending machine

- Shuz Tung CNC 50BR2 3D tube and profile bender

- BPR CPS 60 three-roller pipe bender

- Pipe diameter reducer Mille Miglia DS70

- Hydraulic presses 40 and 240 tons

- 4 eccentric presses from 25 tons to 40 tons

- Vimercati PHY75 CNC edge press

Cutting

Band saws:

- Bromar Proline 420.350 ANC-SX

- Bromar Workline 610.450 DGH

- Bromar EasyCut 275.230DG

Disc saws:

- Macc New 250 DV

- Macc NTS 315

Sheet metal cutting:

- Vimercati CSI 3006 – Sheet metal guillotine

- BODOR P3 6kW – Laser cutting

Machining

Conventional lathes:

- Fat TUR 630X1000

- Poręba TPC90

Pillar drilling machines:

- Eurometal W35

- Proma E 2020F / 400

- Proma B-1832FN / 400

Other:

- Lagun FU1100 milling machine

- Grinding shop with 5 stationary belt grinders from the company FEIN Grit GX 75 2H

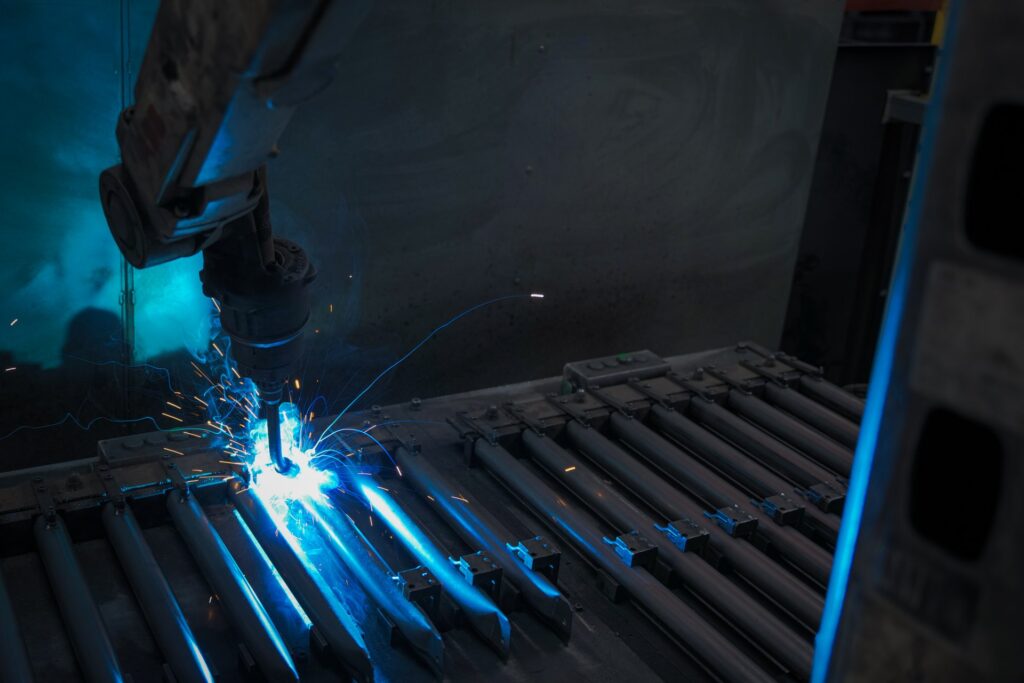

Welding and heat sealing

- 6 Fronius semi-automatic MIG / MAG welding machines

- 4 TIG welders

- Robotic welding cell with ABB IRB 2600ID robot and Fronius TPS500i welding machine

Spot column welders:

- ASPA ZPm 25

- ASPA ZPn 25

- PEI BSP 226 S1

- PEI PBP 151PX1600

- 2 TECNA 7900 hand welding machines

Application of coatings

Thanks to our machine park and qualified staff, we provide coating application by:

- Enamelling

We apply electrostatic enamels with applicators of the Swiss company GEMA. We have two application stations – one is robotic for large series and the other is manual for trials and smaller series. Firing takes place in two Nabertherm chamber furnaces. - Painting with solvent-based paints

We spray paint in a professional spray booth with two WAGNER applicators – electrostatically with the Puma 28-40 pump and classically with the Leopard 48-100 pump. - Powder painting

Our two lines of a powder coating shop and an automatic EKOMAL line for surface preparation ensure high quality and efficiency of the painting process. We work with GEMA applicators. Stability and a final effect of the painting process are ensured by baths with the products of the potentate on the chemical market – company HENKEL

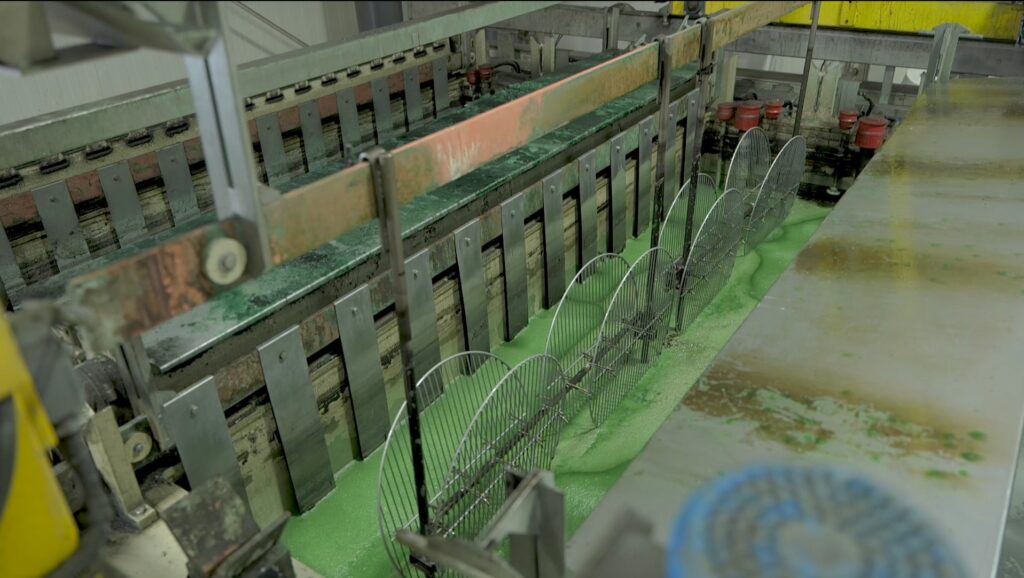

Stainless steel electropolishing

The automatic line for polishing stainless steel through the DELMET electrolysis process guarantees the highest quality of this process.

Assembly and preparation of shipment

We pack products on two automatic picking lines and stationary in 6 assembly rooms. Individually developed packaging designs allow you to protect and take care of every detail of the customer’s product.

Production of prototypes and small series

The well-equipped prototype stand has two large Siegmund welding tables, which, combined with a wide range of equipment, allow for rapid and precise implementation of prototype projects.